How do I use the mass flow controller?

Follow these steps when using a mass flow controller:

- Connect the piping.

- Conduct the leak check.

- Make the necessary electrical connections (power supply, set voltage, etc.).

- Turn on the power supply and check if there’s any deviation from the zero point.

- Apply pressure to the upstream side of the MFC to apply differential pressure to the mass flow controller.

- Enter the flow rate you want to set in the mass flow controller.

1.Piping connection

Pipe diameter

The typical diameter of piping used in mass flow controllers is 1/4 inch (approximately 6.35 mm). Depending on the fluid and flow rate, piping diameters such as 1/16 inch, 1/8 inch, 3/8 inch, and 1/2 inch are also used. Therefore, it is necessary to choose MFC fittings to match the pipe diameter.

Fittings

VCR type and Swagelok tube fittings are the most popular mass flow controller fittings.

VCR Type

VCR fittings come in male and female types; mass flow controllers usually employ male fittings. Place the metal gasket between the male and female fittings of the MFC and the piping respectively, tighten the nut on the female side by hand, and then tighten it further with a 1/8 turn with a wrench. (The procedure can be different depending on the gasket material.)

Swagelok Tube Fittings

Tube fittings are also called Swagelok fittings, and consist of a fitting, a nut, and a ferrule on the mass flow controller side. Pass the nut and ferrule through the piping, insert it into the fitting, and tighten the nut to make the connection.

What are the key points for using the mass flow controller with high accuracy?

- After turning on the power, warm up for about 30 minutes. When turned on the power, the thermal sensor will heat up, but the warming up improves stability.

- Press zero point reset with the gas completely stopped. For more information, please click here.

- Keep signal cables as short as possible. Setting signals and output signals are 0-5V voltage signals. Long cables can cause signal degradation due to voltage drop.

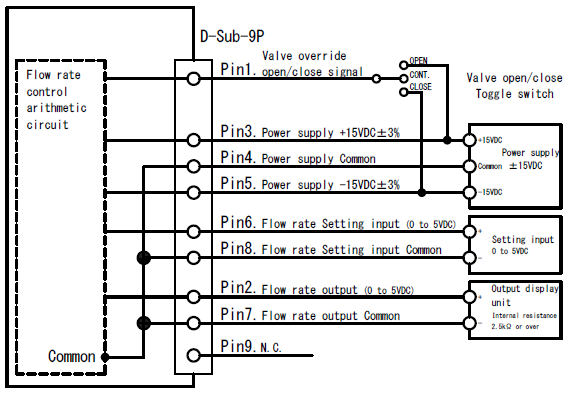

- Do not connect Flow rate setting signal COMMON[8],Flow rate output signal COMMON[7], and Power supply COMMON[4] in the power supply unit.

- Keep the supply pressure stable to avoid sudden pressure fluctuations. This will minimize the impact of flow control.

- When using liquefied gas, please heat the piping to avoid creating the cold spots in the piping. When re-liquefaction occurs, it will cause the rapid pressure fluctuations and lead to the flow instability.

These are the key points for using mass flow controllers with higher accuracy. By paying attention to these precautions, high accurate flow control can be achieved.