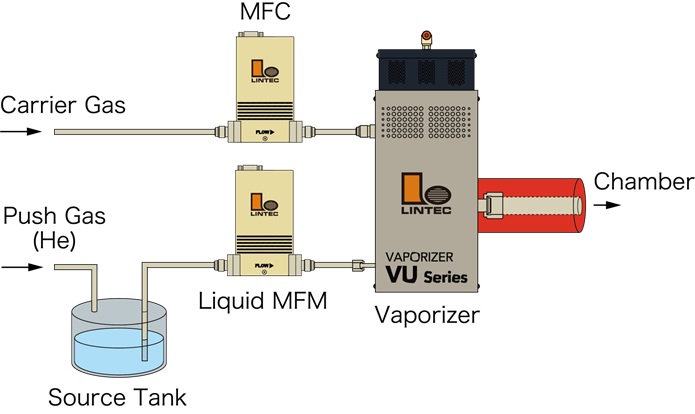

This method utilizes a liquid mass flow meter to measure the liquid mass flow rate and a vaporizer to control the flow rate and vaporize the liquid.

Basic Principles of Direct Vaporization Method

The precursor is being constantly supplied to the vaporization chamber; first the flow rate is measured with a liquid mass flow meter, and then the measured flow rate is controlled by a valve built in the vaporizer.

Continuous flow of the liquid precursor is vaporized instantaneously upon entering the vaporization chamber.

The precursor is being supplied and controlled in it’s liquid form, but given the instantaneous vaporization, the mass of the vaporized precursor remains the same. Due to this factor, it can be concluded that the liquid mass equals the vapor mass.

This method provides high stability since the vapor concentration is controlled directly with an MFC, and, unlike bubbling, makes possible vaporization with high vapor precursor concentration.

Features

- The upstream line of the vaporizer doesn’t require temperature control

- Excellent accuracy and stability due to direct flow control

- Vapor can be supplied under reduced or atmospheric pressure conditions

- Capable of supplying high flow rates of vapor

Vaporizer Product List

Atomizing Vaporizers

A vaporizer that heats a flow-controlled liquid and carrier gas to reduce the partial pressure ratio of the liquefied gas to provide a stable vaporization supply.

Compact Vaporizer [VU-206]

Compact Vaporizer [VU-206]

- Maximum vaporization rate of H2O: 0.5g/min

- Maximum vaporization rate of TEOS: 0.7g/min

- Maximum operating temperature: 160°C

High Efficiency Vaporizer [VU-430]

High Efficiency Vaporizer [VU-430]

- Maximum vaporization rate of H2O: 1.0 g/min

- Maximum vaporization rate of TEOS: 10g/min

- Maximum operating temperature: 200°C

![High-efficiency vaporizer [VU-450]](https://ld7wbevg6gkl.cdn.shift8web.com/en/wp-content/uploads/2023/07/VU-0450N.jpg) High Efficiency Vaporizer [VU-450]

High Efficiency Vaporizer [VU-450]

- Maximum vaporization rate of H2O: 5g/min

- Maximum vaporization rate of TEOS: 20g/min

- Maximum operating temperature: 200°C

High Temp. Vaporizer [VU-550]

High Temp. Vaporizer [VU-550]

- Maximum vaporization rate of H2O: 5g/min

- Maximum vaporization rate of TEOS: 20g/min

- Maximum operating temperature: 300°C

![High Efficiency Vaporizer [VU-440]](https://ld7wbevg6gkl.cdn.shift8web.com/en/wp-content/uploads/2023/07/VU-0440N.jpg) High Efficiency Vaporizer [VU-440]

High Efficiency Vaporizer [VU-440]

- Maximum vaporization rate of H2O: 5g/min

- Maximum vaporization rate of TEOS: 30g/min

- Maximum operating temperature: 200°C

![Large Flow Vaporizer [VU-462]](https://ld7wbevg6gkl.cdn.shift8web.com/en/wp-content/uploads/2023/07/VU-0462N.jpg) High Flow Vaporizer [VU-462]

High Flow Vaporizer [VU-462]

- Maximum vaporization rate of H2O: 15g/min

- Maximum vaporization rate of TEOS: 50 g/min

- Maximum operating temperature: 300°C

![Light Contact Vaporizer [VU-900]](https://ld7wbevg6gkl.cdn.shift8web.com/en/wp-content/uploads/2023/07/VU-900.jpg) Light Contact Vaporizer [VU-900]

Light Contact Vaporizer [VU-900]

- Maximum vaporization rate of H2O: 7g/min

- Maximum operating temperature: 200°C

Quartz Vaporizer QV-1000

Quartz Vaporizer QV-1000

- Maximum vaporization rate of H2O: 15g/min

- Maximum operating temperature: 200°C

Non-Carrier Vaporizers

Vaporizers capable of supplying vapor without carrier gas with low pressure fluctuations.

Related Products

Vaporizers: Features and Options

High Efficiency Vaporization

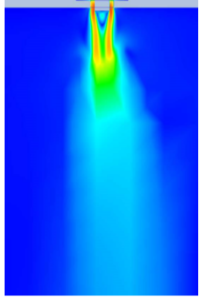

Venturi effect occurs in the double fluid nozzle, which combines the carrier gas and flow-controlled liquid nozzles. The liquid droplets are sprayed straight down the vaporization chamber, which ensures a stable and constant liquid supply, even at lowest flow rates. Atomized mist is then efficiently vaporized by being exposed to radiant heat and by contacting with the inner walls of the vaporization chamber.

Low Flow Rate Vaporization

Flow flow rate control can be very tricky, and often requires precise adjustment of the control valve, a piezoelectric actuator, and minimalization if the dead volume between the fluid control part and the vaporization chamber.

High 300℃ Operational Temperature

Thin film formation processes, such as CVD and ALD, often require vapor supply of organometallic precursors with low vapor pressure and higher than 200℃ boiling point. Lintec’s vaporizers are remarkable due to their ease of maintenance and heat resistance, which are achieved through the use of metal seal materials and heat-resistant structure.

Maintainability

A vaporizer’s life cycle highly depends on the physical properties and purity of the precursor material. Thus, periodic maintenance is sometimes deemed necessary, depending on the vaporized precursor material. Lintec’s vaporizers are designed to enable easy maintenance and reduce the maintenance costs.

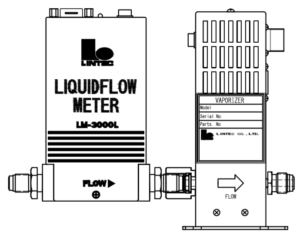

Close Proximity Valve Structure

The control valve of the vaporizer is located in close proximity to the vaporization chamber and receives a flow control signal from the liquid flow meter. This construction minimizes the dead volume, which improves the response speed of controlling the flow rate of the liquid entering the vaporization chamber.

Multiple Liquid Flow Control Valves

It is possible to vaporize numerous liquids simultaneously or one-by-one by installing multiple liquid flow control valves close to the vaporization chamber.

Valveless Construction

Lintec also provides vaporizers with a valveless construction, i.e., without a liquid flow control valve. It is possible to use such vaporizers with liquid mass flow controllers already at hand, for example, as a set with Coriolis sensor mass flow controllers that don’t require C.F. calculation.

High Flow Rate Vaporization

High flow rate vaporization is achieved by a unique extended vaporization chamber design that maximizes the effect of radiant heat.

Compact design

Lintec provides compact vaporizers that only require 78mm of face-to-face space. Even when connected in chain with a mass flow meter, this design requires only 203mm in total.

![Non-carrier vaporizer [VU-3000]](https://ld7wbevg6gkl.cdn.shift8web.com/en/wp-content/uploads/2023/07/VU-3000.jpg) Non-Carrier Vaporizer [VU-3000]

Non-Carrier Vaporizer [VU-3000]