Liquid Mass Flow Controller & Meter (LFC/LFM) Operating Principle

Liquid mass flow controllers and meters automatically control and measure the liquid flow rate, respectively. The two main operating principles of a mass flow controller are mass flow measurement via heat capacity and mass flow control via valve angle adjustment using PID.

Lintec’s Liquid Mass Flow Controller Features

Lintec’s liquid mass flow controllers and meters (LFC/LFM) are widely used in the semiconductor industry for the vapor supply of TEOS and other liquid precursors and were the first liquid MFCs introduced to the market.

Mass Flow Control of a Liquid

Liquid mass flow controllers (LFC/LFM) have become indispensable in the semiconductor industry due to their impeccable accuracy and stability properties, outclassing other technologies such as volumetric flow meters and current meters.

High Accuracy

In semiconductor manufacturing, thin film deposition is conducted by vaporizing and applying TEOS and other liquid precursors, which are more affordable and easy to use than gases. The need for a larger liquid supply is growing along with semiconductor manufacturing scale, which is why new low-vapor pressure precursors are being used. Since the previous baking vaporization method using a high-temperature gas MFC was limited by the liquid supply amount and maximum temperature restrictions, a highly flexible direct vaporization method was introduced. However, because the direct vaporization method controls the flow rate of the reactant gas in liquid form, even little errors can have a significant impact on the reaction.

Using H2O as an example, 1 ml of the fluid in the liquid phase expands to 1,244 ml when vaporized under ideal conditions. High-accuracy liquid mass flow controllers (LFC/LFM) are indispensable in semiconductor tools that require accurate liquid control and vaporization to conduct stable reactions.

High Stability

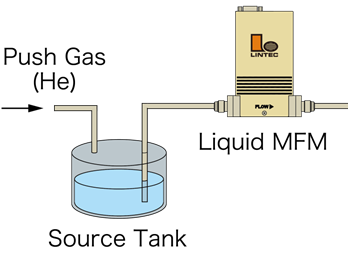

Flow control devices for liquids include metering pumps, but metering pumps continuously perform mechanical switching, which causes pulsation. Syringe pumps, which do not have mechanical switching, do not pulsate, but they are not suitable for continuous supply due to the limited volume of the pump. Also, when liquid is introduced into a vacuum system at a controlled flow rate, the flow rate is not stable with a metering pump due to differential pressure. In the case of a liquid mass flow controller, liquid pressurized to a certain pressure by push gas is introduced, and the instantaneous flow rate is detected by the internal flow sensor. The valve opening degree is then constantly controlled, thus enabling constant flow control whether the secondary side is under reduced pressure or atmospheric pressure.

Liquid Mass Flow Controller (LFC) & Meter (LFM) Lineup

Liquid Mass Flow Meter (LFM)

High Performance Liquid Mass Flow Meter [LM-3000L]

Features: minute flow rate measurement, PID control signal (when used with a vaporizer (VU) or a control valve (CV), metal seal, clean particle-free construction

Options: high-temperature operation support

Liquid Mass Flow Controller (LFC)

Features: minute flow rate measurement, PID control signal, metal seal, clean particle-free construction

Mass Flow Controller Technology Applied Products

Control Valve for Liquids [CV-1000]

Features: proportional solenoid valve, metal seal, clean particle-free construction