Connection examples of Lintec products and various accessories required to use Lintec products (mass flow controllers, vaporizers, heat exchangers).

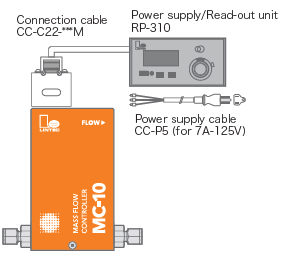

Power Supply/Read-Out Unit for MFC [RP-310]

By connecting one Lintec mass flow controller and one Power Supply/Read-Out Unit for MFC (RP-310) with a dedicated cable, it is possible to set and read out the flow rate (both current and totalized) via analog communication.

Examples of Use

- Sensible MFC flow rate setting with potentiometer

- Stand-alone MFC flow control

- Display of the totalized flow rate of the MFC

- Flow control of MFC in both local and remote modes (host PLC)

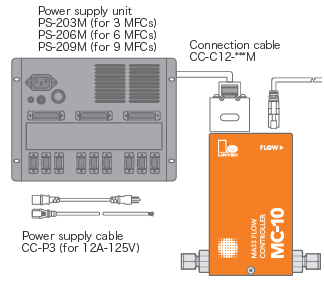

Power supply unit for MFC [PS Series]

By using the power supply unit (PS Series), which can connect up to 9 mass flow controllers, multiple MFCs can be controlled by a PC, PLC, or other means.

Examples of Use

- Power supply for MFC digital control from a PC (e.g. LabVIEW)

- Power supply for MFC control from a PLC

MFC in-line monitor [IM-10]

By connecting an in-line monitor (IM-10) between the mass flow controller and the equipment power supply, input signals, output signals, valve open/close signals, and power supply voltage voltages are measured. The operation of the mass flow controller can be checked inline.

Examples of Use

- Check supply voltage (±15V) to MFC

- Check the MFC flow rate setting value (0 to 5V)

- Check the MFC flow output value (0 to 5V)

- Check the MFC valve open/close signal

Temperature Control Unit [TCU Series]

Temperature control unit provides power supply and allows temperature adjustment for Lintec heat exchangers (HX series), liquid vaporizers (VU series), or other products that require temperature control.

![Connection Diagram for Temperature Control Unit]](https://ld7wbevg6gkl.cdn.shift8web.com/en/wp-content/uploads/2023/07/Connection-Diagram-for-Temperature-Control-Unit.png)